3D Experiences

for Architecture,

Construction,

Advertisement &

Industrial Innovation

3D Experiences

for Architecture,

Construction,

Advertisement &

Industrial Innovation

“We replace costly photoshoots and ad production with cinematic 3D visuals that save you time and money.”

“We help architects, developers, and industrial clients turn designs into immersive 3D, VR, and digital twins that speed decisions and reduce risk and cost.”

“We help architects, developers, and industrial clients visualize, test, and communicate projects before they’re built.”

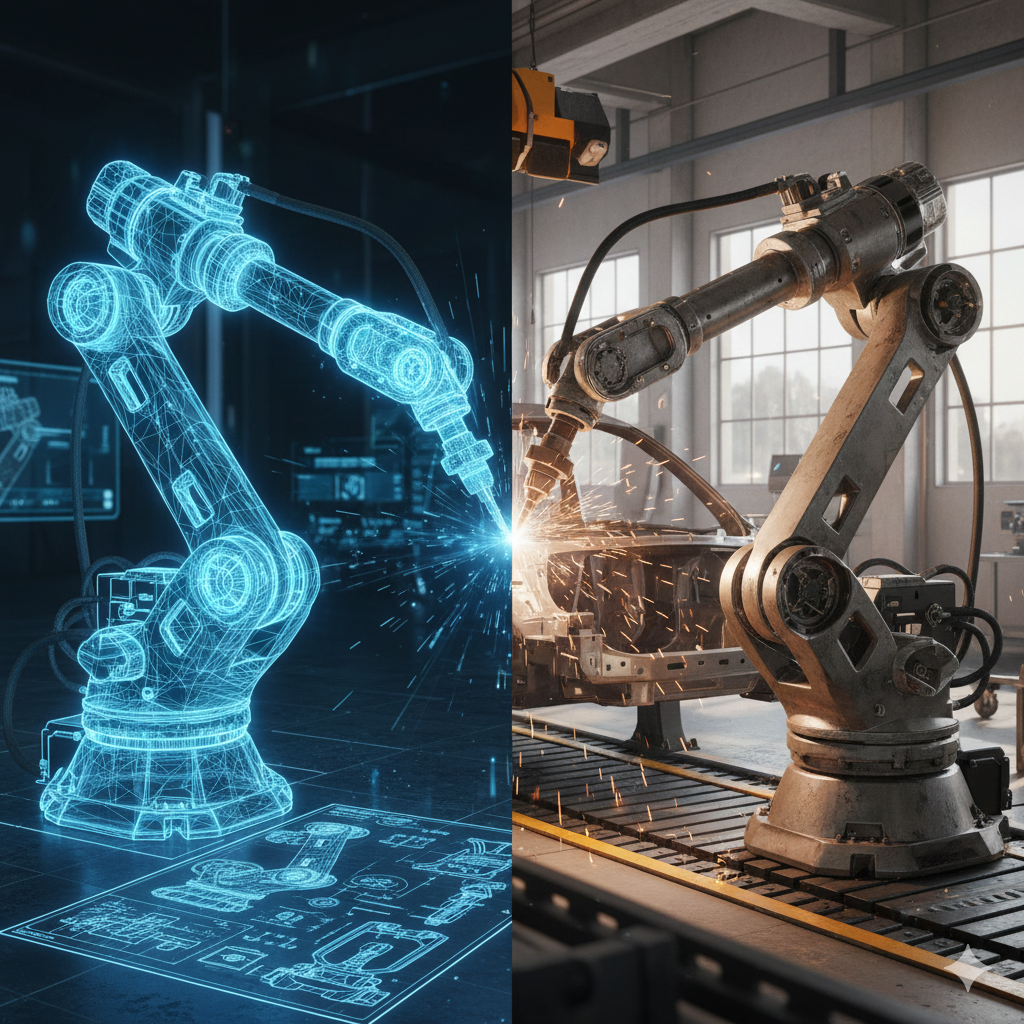

DIGITAL TWIN

Robotics, Architecture, Industrial Digital Twin Solutions – We create high-fidelity virtual replicas of robotic systems, architecture, development project visualization.

How we do it?

Discovery & Requirements

Client Consultation – Identify the robotic systems (AMRs, cobots, automation cells) and the intended use cases of the Digital Twin (design validation, commissioning, training, reconfiguration).

Data Intake – Collect CAD drawings, BIM models, PLC logic, sensor layouts, and production line schematics from the client.

Use Case Definition – Determine how the twin will be used (layout optimization, operator training, predictive maintenance, etc.).

CAD Parsing & Cleaning – Import STEP/IGES/SolidWorks files into conversion pipelines. Analyze assemblies, joints, and tolerances.

Replication in DCCs – Rebuild and optimize CAD data into 3ds Max (for precise modeling), Houdini FX (for procedural assets, robotics kinematics), and prepare USD-compatible geometry.

Data Fidelity & Simplification – Balance engineering accuracy with optimized geometry for simulation/visualization, ensuring correct joint hierarchies and scale.

3ds Max – Refine and detail high-quality robotic and environmental assets based on CAD references.

Houdini FX – Create procedural rigs and simulations (robot motion arcs, conveyor flow, material handling).

Material Optimization – Apply PBR materials for real-time compatibility in Omniverse and Unreal Engine.

Integration into NVIDIA Omniverse

USD Workflow – Export CAD-derived DCC assets into USD format.

Nucleus Server – Manage version control and enable multi-user live collaboration.

Omniverse Isaac Sim – Validate robotics kinematics, path planning, and sensor data inside a physics-accurate simulation environment.

Simulation & Virtual Commissioning

Omniverse Physics & AI – Test CAD-based designs virtually before hardware build.

Scenario Testing – Run throughput simulations, robot collisions, and operator safety cases.

Iterative Loops – Rapidly reconfigure layouts by editing CAD-informed Digital Twin assets inside Houdini and Omniverse.

Immersive Visualization & Stakeholder Review

Unreal Engine – Present CAD-derived robotic systems in photoreal, interactive VR/AR environments.

Operator Training – Provide immersive simulations for engineers to “walk through” the robotic cells and test workflows before deployment.

Design Review Loops – Allow stakeholders to mark up and adjust CAD-informed assets in real-time via Omniverse collaboration.

Delivery & Lifecycle Support

Deployment – Deliver the twin as a continuously updated USD environment.

Integration – Connect real PLC/IoT data streams to the twin for live monitoring.

Ongoing Reconfiguration – Use CAD-to-DCC pipelines to update layouts whenever the physical line evolves.

FILM & VFX

We specialize in crafting compelling 3D models, animations, and visual effects, transforming concepts and brand identities into captivating visual narratives. Our skilled artists seamlessly integrate CGI/VFX elements into live-action footage, pushing the boundaries of innovation for virtual prototyping and Augmented Reality experiences.

How we do it?

1. 3D Modeling and Animation:

Immerse your audience in captivating visual journeys with our expert 3D modeling and animation services. NK brings life and dynamism to your ideas through precision and creativity.

2. Visual Effects (VFX):

Elevate your films, commercials, or presentations with seamless Visual Effects crafted by NK|Immersive Media. Our CGI experts seamlessly blend computer-generated elements with live-action footage, creating awe-inspiring spectacles.

3. Virtual Prototyping:

Propel your product development forward with NK’s CGI expertise in virtual prototyping. Visualize and refine your concepts in a virtual environment, saving time and resources in the physical production stage.

4. Architectural Visualization:

NK transforms architectural concepts into immersive experiences, exceeding traditional renderings. Collaborate with our CGI artists to showcase projects with stunning visualizations that captivate clients and stakeholders.

5. Custom Graphics and Branding:

NK|Immersive Media crafts bespoke CGI graphics to elevate your brand identity. Collaborate with us to create visuals that uniquely resonate with your brand, leaving a lasting impression on your audience.

6. Virtual Reality (VR) Experiences:

Experience the fusion of virtual and real worlds with NK’s CGI-driven Virtual Reality experiences. Engage your audience with interactive and immersive brand interactions that break conventional boundaries.

Embark on a visual journey with NK|Immersive Media, where imagination meets pixel perfection. Our commitment to CGI innovation ensures that your projects receive visual solutions that not only captivate but also inspire. Whether for marketing, entertainment, or design, NK|Immersive Media is dedicated to exceeding your expectations. Join us and let’s bring your visions to life like never before.

We create engaging and dynamic motion graphics that help you communicate your message in a memorable and impactful way. Our motion graphics are designed to be shareable and help you increase engagement and conversions.

CAD 2D drawings to 3D models. We transform architectural/product concepts into immersive 3D and Virtual Reality experiences using advanced technologies. Our services cater to both 3D visualization and VR experiences, perfect for marketing presentations and design verification.

⭐ Oil & Gas Industry Testimonial

“With NVIDIA Omniverse, we created a digital twin of our offshore operations. Simulating pipelines and refinery systems in 3D allowed us to test safety protocols, reduce downtime, and optimize energy use. It’s transformed how we plan and execute complex oil & gas projects.”

— Operations Director, Global Oil & Gas Company

⭐ Beverage Industry Testimonial

“Omniverse gave us the ability to simulate our entire bottling line before installing new equipment. By visualizing workflows and planning expansions in 3D, we reduced downtime, cut costs, and improved sustainability metrics. The immersive digital twin environment is a game-changer for beverage manufacturing.”

— Plant Manager, International Beverage Manufacturer

⭐ Automotive Industry Testimonial

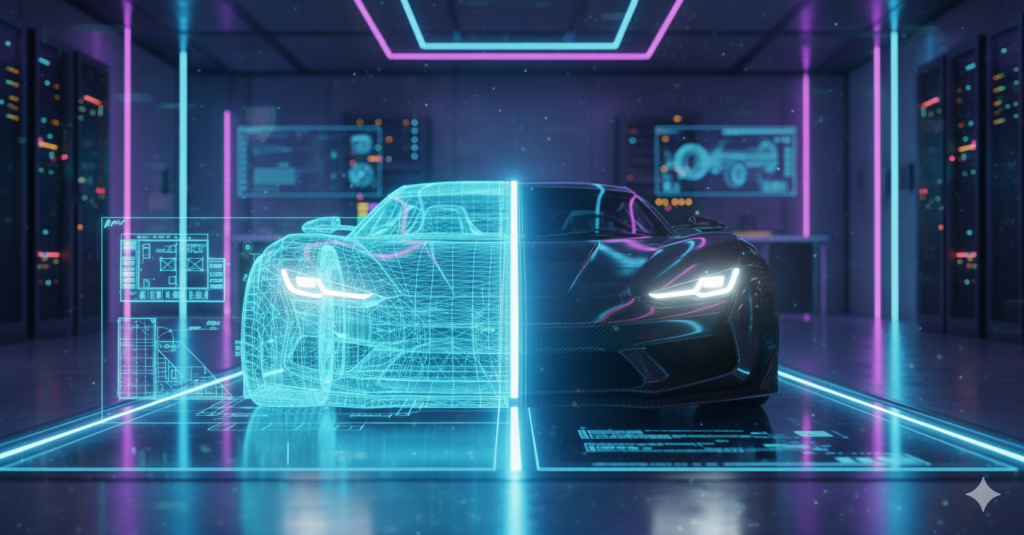

“At our automotive plant, training robots in Omniverse saved months of trial-and-error. We built an immersive digital twin of the assembly line, optimized welding automation, and tested safety protocols virtually. Efficiency and precision have never been this high.”

— Head of Robotics, Leading Automotive Manufacturer

⭐ Construction Industry Testimonial

“Omniverse allowed us to visualize every construction phase in real time and simulate sustainability metrics dynamically. From commercial towers to residential projects, digital twins helped us deliver safer, greener, and more efficient buildings. The immersive collaboration has unified our entire team.”

— Project Director, Global Construction Firm

ARTICLES NVIDIA Omnivers IsaacSIm

NVIDIA Omnivers IsaacSIm Digital Twin Applications: Planning, Simulation, and Operations Explained Digital Twin Applications are transforming industries—from

NVIDIA OMNIVERSE CONSTRUCTION INDSUTRY

NVIDIA OMNIVERSE CONSTRUCTION INDSUTRY The NVIDIA Omniverse architecture construction ecosystem is transforming how the industry tackles challenges like

NVIDIA OMNIVERSE CAR MANUFACTORING

NVIDIA OMNIVERSE CAR MANUFACTORING By NK Immersive Media – with insights from Nicco Kuc Defining the Problem Manufacturers

NVIDIA OMNIVERSE CONSTRUCTION INDSUTRY

NVIDIA OMNIVERSE CONSTRUCTION INDSUTRY At NK Immersive Media, we recognize the constant pressure the construction industry faces to

NVIDIA OMNIVERSE CAR MANUFACTORING

NVIDIA OMNIVERSE CAR MANUFACTORING The automotive industry is changing rapidly. At NK Immersive Media, we see how rapidly

NVIDIA OMNIVERSE BEVERAGE

NVIDIA OMNIVERSE BEVERAGE The beverage industry is under constant pressure to meet rising consumer demand while maintaining

NVIDIA OMNIVERSE REFINERY

NVIDIA OMNIVERSE REFINERY Author: Nicco Kuc The oil and gas industry is entering a new era of

Uncategorized

Uncategorized A Balanced Perspective on Recent Controversies The Adobe platform has long been a cornerstone

ABOUT USMeet Nicco Kuc, the visionary founder of NK Immersive Media, a global CGI powerhouse based in UAE Dubai. Nicco leads a diverse team of vetted graphic artists, each bringing a unique perspective. With a commitment to innovation, he translates architectural visions and brand identities into immersive visual narratives. Nicco’s leadership reflects a belief in limitless possibilities through collaboration. Join us on this global creative odyssey guided by our founder, Nicco.